Optical bonding means bonding in between the LCD display and the cover glass by using the optical adhesives: Optical Clear Resin(OCR) / Optical Clear Adhesive(OCA).

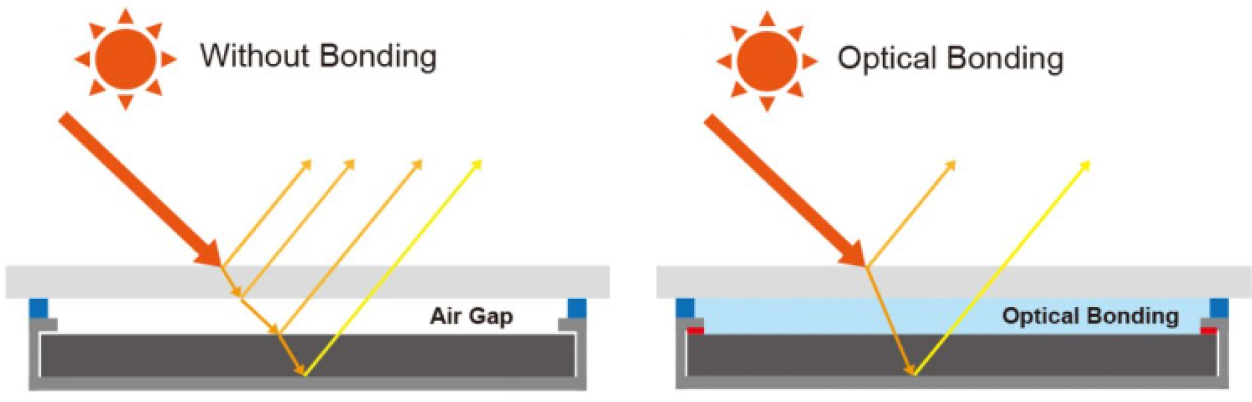

When industrial displays are used outside or indoors, cover glasses are used to protect the displays, while the air gap between the LCD display and the cover glass is vulnerable to humidity or dust depending on the environment, and reflects light from the outside, thereby deteriorating the visibility of the LCD display. Optical bonding improves the performance of displays by eliminating air gaps between the LCD display and the cover glass.

Silicone adhesives have been used for over 30 years for bonding commercial and military displays. It has the advantage of being easy to rework due to its soft material properties. Due to the characteristics of the product, the adhesion is not strong, so there is a disadvantage that you need to be careful about the adhesion of the edges. For this reason, we seal the edges of the bond with a thin black tape or abrasion of the edges when in use.

Another adhesive we use is an acrylic formulation. It has a much tighter bond than silicon, but there is no formation of particulate debris. Rework is not possible if problems arise during production or use. However, for some designs where the use of tape to seal the edges is difficult, this may be the option of choice.

Optical transparent adhesive product made in liquid form for optical bonding of display and touch panel. OCR enables operation in large size optical bonding.

Optical transparent adhesive product made in film form for optical bonding of display and touch panel. With excellent transparency identical to optical parts even under the condition of refraction and high humidity, high temperature, it is an UV curable optical transparent adhesive most ideal for bonding displays and touch panels. OCA enables fast operation in small to medium size optical bonding.

Optical transparent adhesive product made in liquid form for optical bonding of display and touch panel. OCR enables operation in large size optical bonding.

We provide high quality display glasses with various thickness and surface treatment options such as fine matte anti-glare, multi-layer anti-reflective and conductive ITO coating.

Chemical strengthening and silk screen printing are also available.

EMI/RFI Shields protects the system from Electromagnetic interference (EMI), which causes electromagnetic interference, malfunctions due to noise, and signal quality that cause system degradation in electronic equipment and system operation and it is necessary for applications that provide high electrical properties.

EMI (Electromagnetic Interference) shielding is implemented by using the latest products such as Metal Mesh, etc.

Reflects near IR heat with minimal reduction of visible light transmission